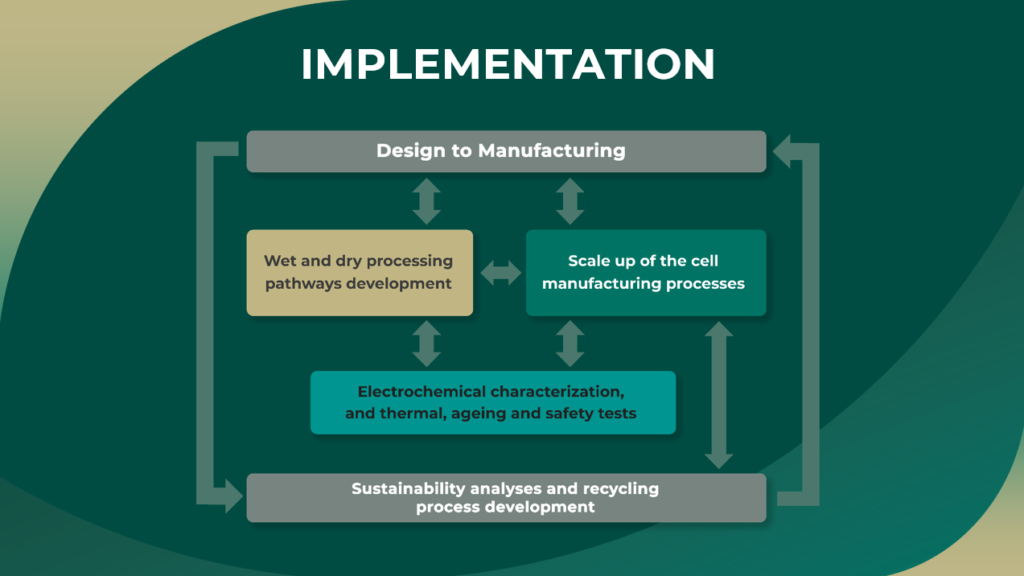

GIGAGREEN proposes a structured research plan to develop and scale up novel electrode and cell component manufacturing processes that follow a Design to Manufacture approach in line with Europe’s strategic goal of becoming a global leader in the Li-ion battery value chain.

This means that GIGAGREEN seeks for the minimum environmental impact and energy consumption, cell designs which facilitate the re-use and disassembly, increase of the cost-efficiency and safety of processes and products, and high-throughput technologies able to be easily scaled up and automated in the context of industry 4.0/5.0 gigafactories.

GIGAGREEN will finalise by the end of the project with a set of novel materials (binders, electrolyte, separators, cathode, and anode active materials, etc.), adapted to innovative dry and wet electrode processing techniques, which motivate the generation of Design to Manufacture guidelines and a data-driven Digital Twin.

GIGAGREEN proposes a sustainable and cost-efficient new approach by integrating synergies and materials within the recycling and production chain of the new battery systems. Apart from recycling the metals (Cu, Ni and Al) and plastics, GIGAGREEN aims to recycle both active materials and electrolyte.

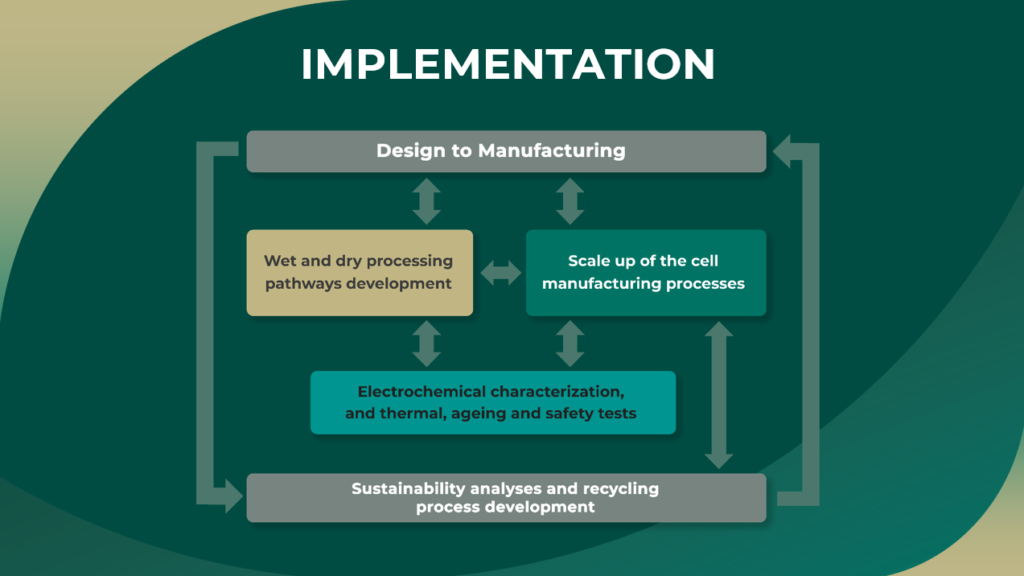

GIGAGREEN proposes a structured research plan to develop and scale up novel electrode and cell component manufacturing processes that follow a Design to Manufacture approach in line with Europe’s strategic goal of becoming a global leader in the Li-ion battery value chain.

This means that GIGAGREEN seeks for the minimum environmental impact and energy consumption, cell designs which facilitate the re-use and disassembly, increase of the cost-efficiency and safety of processes and products, and high-throughput technologies able to be easily scaled up and automated in the context of industry 4.0/5.0 gigafactories.

GIGAGREEN will finalise by the end of the project with a set of novel materials (binders, electrolyte, separators, cathode, and anode active materials, etc.), adapted to innovative dry and wet electrode processing techniques, which motivate the generation of Design to Manufacture guidelines and a data-driven Digital Twin.

GIGAGREEN proposes a sustainable and cost-efficient new approach by integrating synergies and materials within the recycling and production chain of the new battery systems. Apart from recycling the metals (Cu, Ni and Al) and plastics, GIGAGREEN aims to recycle both active materials and electrolyte.